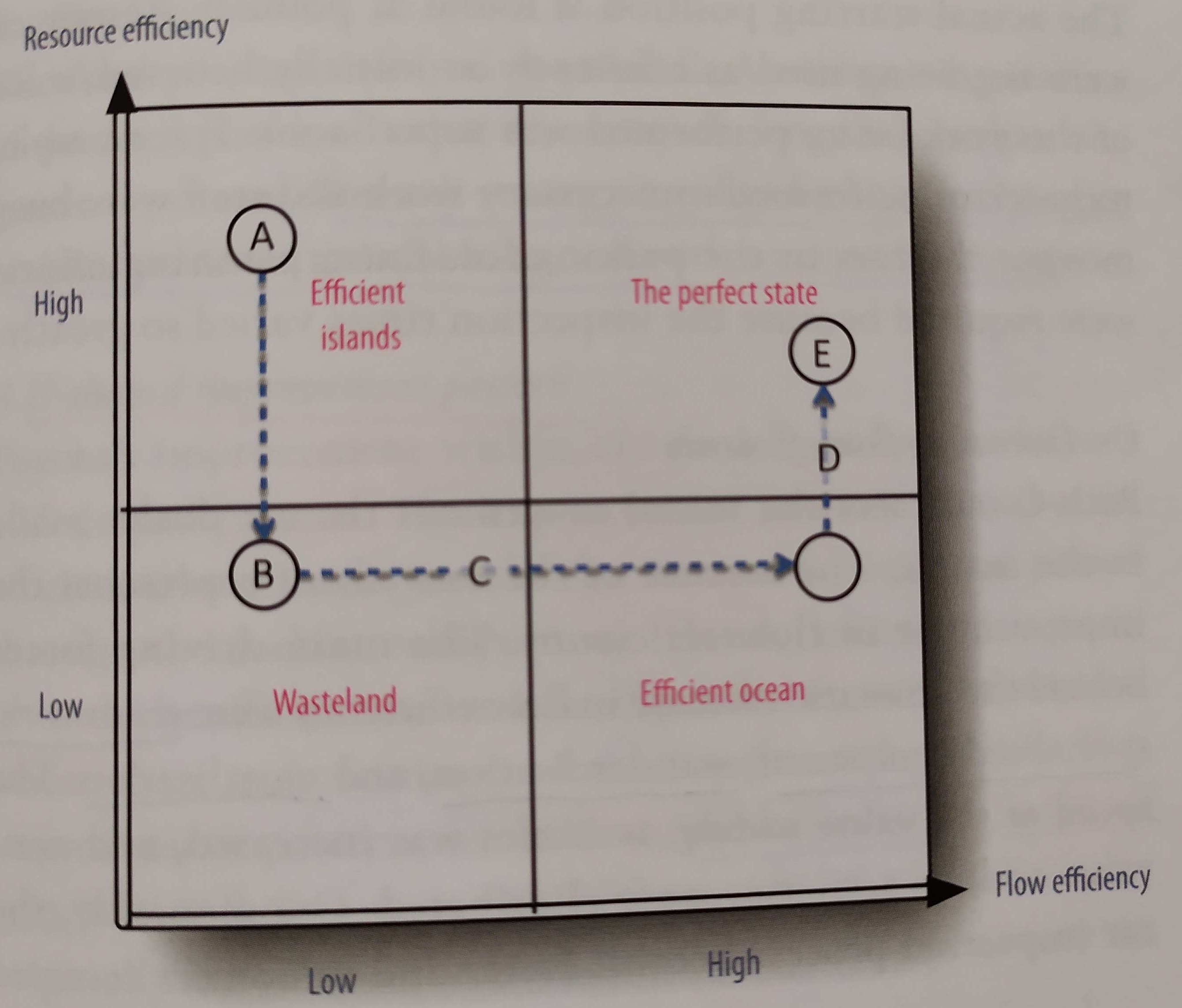

Model: Lean improvement pattern: U-shaped

this improvement pattern, shows some key traits of lean

example: Toyota Sales Logistics

sales, distribution, service (Japan requires thorough car inspections)

a) perceived starting position

b) actual starting position

a) perceived starting position

b) actual starting position

- lot’s of superfluous work (unnecessary technical work, moving cars, difficult planning)

c) increasing flow efficiency

the speed of the value-adding activities was increased,

and non-value-adding activities were eliminated

- teamwork

- specialized equipment

- standardization

- visualization

d) increasing resource efficiency

- removed superfluous work

- new layout

- specialized equipment

- simpler planning

e) final position

Toyota's strategy involves having free capacity on hand in order to be able to deal with unexpected event

(src: Book: This is LEAN - Niklas Modig & Par Ahlstrom)